Analysis of the causes of tantalum capacitor failure. The full name of lithium capacitor is tantalum electrolytic capacitor , which is also a type of electrolytic capacitor. Solid tantalum capacitors were first developed by Bello Laboratories in the United States in 1956. Tantalum capacitors use tantalum metal as the dielectric. They do not need to use electrolyte like ordinary electrolytic capacitors, nor do they need to use aluminum-coated capacitor paper for firing.

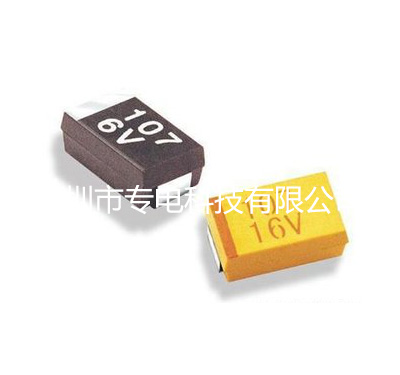

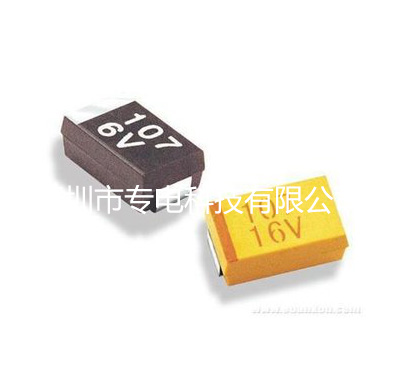

Tantalum capacitor identification method

Lithium electrolytic capacitors are polar capacitors. If they are connected in reverse, they may burn out. How to judge its polarity is also very simple. Just look at it with the naked eye. The positive electrode is where there is a horizontal bar or bevel, and the negative electrode is on the other side.

1. It is a type of electrolytic capacitor. It uses metal tantalum as the medium. It does not use electrolyte like ordinary electrolytic capacitors. Tantalum capacitors do not need to be wound with aluminum-coated capacitor paper like ordinary electrolytic capacitors. They have almost no inductance. But this also limits its capacity. ——We use tantalum capacitors in scenarios where high capacity is required but low ESL is required.

2. Because there is no electrolyte inside the tantalum capacitor, it is very suitable for working at high temperatures. —Some scenarios with relatively wide temperature range requirements.

3. The working medium of tantalum capacitors is an extremely thin layer of tungsten pentoxide film formed on the surface of platinum metal. This layer of oxide film. The medium and one terminal of the capacitor are combined into a whole and cannot exist alone. Therefore, it has a very high operating electric field intensity per unit volume and a very large capacitance, that is, a very high specific capacity, so it is particularly suitable for miniaturization. In scenarios with a relatively high degree of integration, aluminum electrolytic capacitors occupy a relatively large area, and in scenarios where ceramic capacitors have insufficient capacity.

4. Tantalum capacitors have excellent performance. They are small in size and can reach larger capacitance among capacitors. They have few competitors in power supply filtering, AC bypass and other applications. Tantalum electrolytic capacitors have the functions of storing electricity, charging and discharging, etc. They are mainly used in filtering, energy storage and conversion, marking bypass, coupling and decoupling, and as time constant components. Pay attention to its functional characteristics during use. Correct use will help to give full play to its functions. For example, consider the product's operating environment and heating temperature, and take measures such as derating. Improper use will affect the working life of the product.

For example, the USB interface output needs to have a withstand voltage of 5V after derating and a relatively high degree of integration. When ceramic capacitors are not satisfied with high withstand voltage and large capacity, we have to choose tantalum capacitors. The energy storage effect of ceramic capacitors cannot be equivalent to the parallel capacitance, and the price required to achieve the same effect is also very large.

5. The temperature stability of the capacitance value of tantalum capacitors is relatively good. In some coupling and filtering scenarios, if the phase and frequency characteristics of the filter are relatively high, and the capacity accuracy is relatively high, non-polar tantalum capacitors will be used. Such as audio circuit design for high sound quality requirements.

6. During the operation of the capacitor, it has the function of automatically repairing or blocking defects in the oxide film, so that the oxide film medium can be reinforced and restored to its proper insulation capability at any time without suffering continuous cumulative damage. This common self-healing function ensures its advantages of long life and reliability. ——A scenario where the aluminum electrolytic capacitor cannot meet the service life due to dryness.